Screw Lift

Technical Description

1、Product Composition

The screw type of anode jacking device series manufactured by our company is the corollary equipment for pot that use prebaked anode in metallurgical industry which is widely used in pot rooms with high magnetic field, high temperature and full of dust. As the matured finish product of our company for years, the anode jacking device series owns the distinctiveness from design to manufacture process as strong lifting power, stable lifting, long service life, convenient for operation and maintenance, etc. We select the precise machined high quality material as the worm and umbrella gear of redirector and main lifting jack for it has the characteristics to enhance the worm strength and prolong its service life etc. Furthermore, we can design and manufacture all types of jacking device according to the requirement from customers.

2、Equipment Introduction and Performance Description

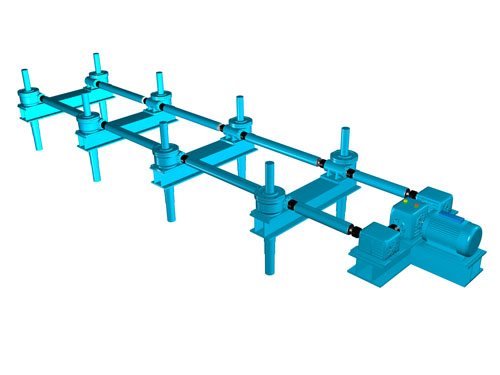

2.1Composition of pot anode jacking device((see Picture 1))

Picture 1 Pot Anode Jacking Device Sketch

Pot anode jacking device is composed of motor, reducer, left jackscrew, right jackscrew, left reversing gear box, right reversing gear box, drive shaft, drive coupling, insulated transmit coupling etc.

The working principle is: The lifting and declining movement is achieved through the drive of cylindrical gear, umbrella gear, and worm gear.

Working process: the motor is used as the power source of the device. First, the device speed is reduced by the reducer. After decelerating, the transmission direction is changed by the reversing gearbox, which is transmitted to the screw crane worm through the main transmission shaft. The worm drives the worm gear to rotate. The center of the worm gear is equipped with a lifting lead screw. The worm gear drives the lead screw to move up and down, and the anode carbon block is fixed on the lead screw.

The left and right jackscrews are composed of worm gear, worm, lead screw, shell, upper end cover, self-aligning bearing, expansion sleeve, etc. The worm gear, worm and lead screw of the drive mechanism are processed by numerical control machine tool, with stable product quality and manufacturing tolerance of ± 0.6 μ M. After processing, they are subject to tempering, tooth surface quenching and carburizing treatment, which are controlled and inspected by professional engineers.The factory delivery rate of the products is 100%.

Picture 2 Left & Right Jackscrew

The Worm of Left & Right Jackscrew (See Picture 3)

In anode jacking device, the function of worm gear is very important. It is related to whether the left and right jackscrews can work normally under large load and whether the service life is long. In this respect, our company has developed a set of new technologies and processes, which have been applied to many customers in aluminum industry with good results (i.e.greatly improved load capacity and longer service life. The material of worm gear is aluminum bronze ZQALl94, which has high strength, hardness and wear resistance. It is a wear-resistant alloy and has good machinability. Its physical properties are very suitable for heavy load operation. In terms of casting technology, our company abandoned sand casting method (the density of the parts cast by this method is small, and it can not guarantee that 100% of the workpieces will not produce air holes in this process), and adopted high-pressure die casting technology, the density of the parts cast by this process is large, and there is no air hole, so the quality of the whole part can be well guaranteed. The products are processed by numerical control machine tool. After processing, the accuracy of products has a qualitative leap, and the load capacity of worm gear has been greatly improved.

Picture 3 Worm

Transmission Shaft (See Picture 4)

In order to increase the strength of the transmission shaft of the jacking device, we select seamless steel pipe and 16Mn as the material of transmission shaft, and 16Mn round steel as the material of the head end and the tail end. The capacity of the transmission shaft has been increased from 1800KN to 2200KN, which greatly enhanced its reliability. The phenomenon of bending deformation of the transmission shaft under heavy load is eliminated.

Picture 4 Transmission Shaft

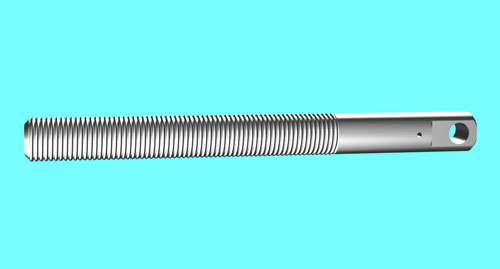

Lead Screw (See Picture 5)

The lead screw is an important part of the jacking device. In order to improve its load capacity and operation stability, the lead screw material is 40gr, which is quenched and tempered after processing, and equipped with trapezoidal thread with heavy load. In order to ensure the lifting speed, the pitch is 16mm, which eliminates the previous problem like heating in operation and damage of the lead screw under heavy load. The temperature rise under full load shall not be greater than 35 ℃, and the noise under full load shall not be greater than 20 dB. The service life shall be no less than 20 years, the reversing of lead screw shall be smooth, and the temperature rise during reversing shall be no more than 45 ℃. The structural performance is good, so does the motion accuracy and repeated positioning accuracy, and the sealing performance is 100%.

Picture 5 Lead Screw

Expansion Sleeve (See Picture 6)

The main function of the expansion sleeve is to protect the lifting lead screw and prevent the potroom dust from entering the interior of the jackscrew. The expansion sleeve is fixed on the lift shell and the lead screw by bolt connection. When the lead screw rotates to produce displacement, the expansion sleeve is stretched or contracted, which plays a key role in the whole working process of the screw lift.

The expansion sleeve is made of 1mm steel plate and galvanized as a whole. The overall structure is divided into four sections, and a polyurethane sealing ring is set between each section to ensure the tightness of the expansion sleeve, and the overall expansion of the expansion sleeve can reach 800mm.

Picture 6 Expansion Sleeve

Coupling Guard (See Picture 7)

The coupling guard is made of cast aluminum with good surface finish and high density; the guard is made of separate parts and positioned by groove during installation, which is convenient for installation and disassembly and accurate for positioning; the seal of the guard is made of silicon rubber, which is resistant to high temperature, corrosion and aging, effectively ensuring the sealing of the coupling, avoiding impurities entering the coupling and affecting the lifting mechanism function.

Picture 7 Coupling Guard

Insulation Sleeve (See Picture 8)

The insulation sleeve is an important insulating part of the anode jacking device. The output shaft of the motor and the double row chain coupling are insulated with polytetrafluoroethylene. Its function is to completely insulate the motor and the reducer, with an insulation resistance of 2m Ω, so as to ensure the normal operation of the motor. Polytetrafluoroethylene is superior in insulation, temperature resistance and mechanical strength.

Picture 8 Insulation Sleeve

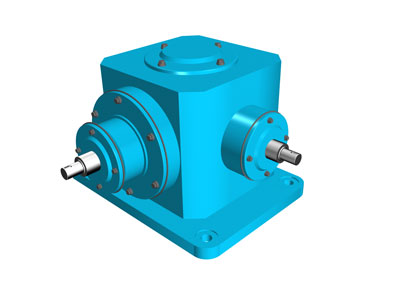

Reversing Gear Box (See Picture 9)

The reversing gear box is the steering mechanism of anode jacking device, which is mainly composed of bevel gear, angular bearing and shell. It is mainly used to reverse the rotating shaft 90 degrees through bevel gear and transfer the rotating force. It can be operated in two directions. There is no dead angle in the two directions of the bevel gear. The tooth surface is processed strictly according to the meshing accuracy of the bevel gear. After assembly and forming, the 20 minute operation test is carried out. During the test, the no-load and 120% overload operation is carried out, including bearing temperature rise, lubricating grease temperature, noise, etc.

Picture 9 Reversing Gear Box

2.10Bevel gear of reversing gear box (See Picture 10)

The bevel gear material in reversing gear box is 20 CrMnTi, with carburizing and tempering treatment applied. The whole shaft is subject to tempering treatment to eliminate stress in shaft body and ensure no stress deformation of shaft body under full load. The bevel gear surface is treated by high frequency quenching, and the hardness of the tooth surface is up to (HRC58-62).

Picture 10 Bevel Gear

2.11Features of Reducer

1) Silent operation: high precision grinding processed gear shape is applied on every smooth rolling contact part of the load transmission mechanism which ensures a smooth and noiseless operation.

2)Small size and space saving: reasonable design and convenient installation is one of the outstanding features of the product.

3)Large torque, high efficiency: because of the elaborate processing, it has very small friction, high efficiency and smooth transmission.

4) Good durability and long service life: it is with reasonable assembly process, stable operation, and low noise. Its raw material is made of steel with good wear resistance and fatigue resistance. The equipment is durable and has a long service life.

5)High operating temperature: suitable for high temperature field.