Anode Jacking Device (Triangle Plate)

Anode Jacking Device

一、Overview

Anode jacking devices are widely used in smelters to lift the prebaked anode required in metal smelting in potrooms with high magnetic field, high temperature and high dust concentration. As our standard equipment for years, it is unique in design to fabrication and is characterized by strong jacking capacity, steady jacking, long service life, easy operation and maintenance, etc. We are able to design and fabricate jacking device of various models in line with customer’s requirement.

The anode jacking devices mainly have two types. One is triangular plate type, and another is screw lift type.

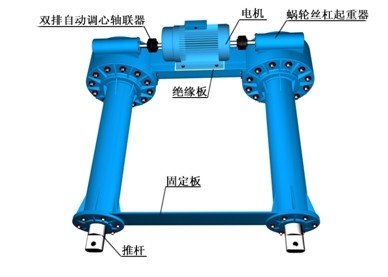

Worm screw lift

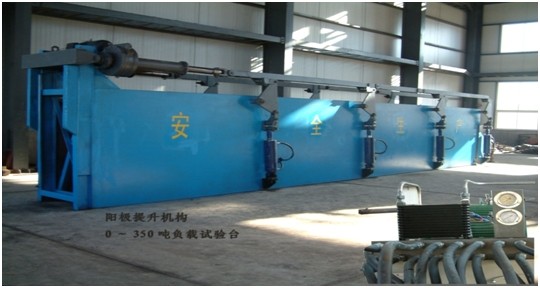

Testbed for triangle plate

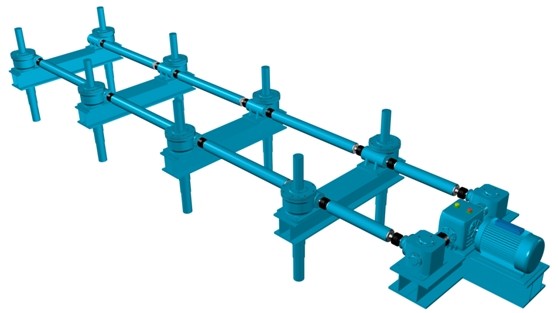

Screw lift

Working principle: the screw lift completes the anode lifting and lowering operation through the cylindrical gear, bevel gear, and worm gear transmission. Working process: the cylindrical gear reducer utilizes motor as the power source to reduce the speed for the first time, after which the reversing gear box changes the transmission direction and transfers power to screw lift worm through main transmission rod and the worm gear drives the lifting screw mounted in the center of it to ascend and descend the anode fixed on the screw.